What Is the Role Of Air Filtration In An Air Distribution System?

Learn More About the Air Distribution Products and Standards That Ensure Excellent Indoor Air Quality

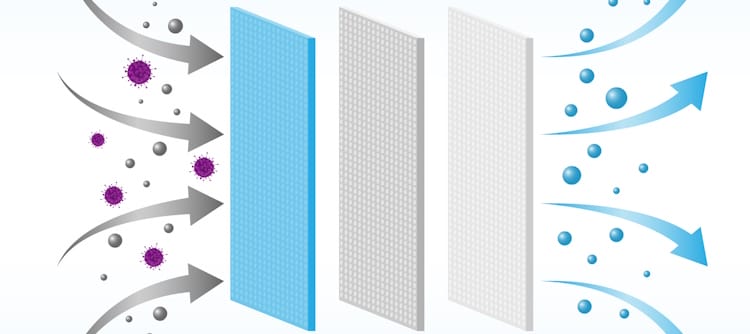

Air filtration refers to the highly precise method of filtering out particulate matter from the air to ensure high indoor air quality (IAQ). Specifically, the role of air filtration is to prevent contaminants and microorganisms from harming human health or affecting materials in an indoor environment.

These unwanted particles include:

- Bacteria

- Viruses

- Fungi

- Dust, debris, and smoke

- Mold spores

- Pollen

Many industries depend on air filtration to achieve acceptable indoor air quality metrics as they undertake key processes, such as pharmaceutical manufacturing, medical surgery, or electronics engineering.

Learn more: Where Are Critical Environment Cleanrooms Used?

What Air Distribution Products Are Used For Air Filtration?

Woven-media filters and fan filter units (FFUs) primarily perform air filtration. Many industries commonly use the following air distribution products:

- HEPA filters: These products use woven fibers to prevent particles from passing through ductwork and into a facility’s air. HEPA filters provide 99.9% minimum removal efficiency for particles .3 microns or larger. Particles that are .3 microns and larger include certain bacteria, dust, and mold.

- ULPA filters: ULPA filters provide an even tighter weave of fibers so they prevent smaller particles from entering a facility’s airspace. ULPA filters have a 99.995% minimum removal efficiency for particles that are .12-microns or larger. For reference, coronavirus particles can be as small as .1 microns. However, it is important to note that viruses travel in “clumps,” which are far larger than a single virus particle. Thus, ULPA filters are highly effective for filtration of even the smallest contaminants.

- FFUs: Fan filter units are air filtration and distribution systems that provide local support for a particular room in a facility, such as a cleanroom. Installers place a fan unit and filter together in the ceiling of the room, allowing the fan to distribute air directly and evenly while the filter cleans it immediately before it enters the space. This provides a highly specific air filtration solution for environments that must adhere to rigorous IAQ standards.

What Additional Air Distribution Products Can Be Used for Air Filtration?

Although ULPA and HEPA air filtration and fan filters are most common, engineers often use other methods for deactivating particulate matter in tandem with filters and FFUs:

- Ionization: Bipolar ionization adds positively and negatively charged ions to the air to add mass to unwanted particles. Their added weight causes these particles to drop out of the air, removing them from the airspace where people are most likely to breathe.

- UV-C light: Ultraviolet light, typically in the form of a lamp, is used as part of some commercial air distribution systems to deactivate particles. Studies have proven that UV-C light kills COVID-19, influenza, and even treatment-resistant bacteria, which often pose challenges for healthcare facilities. UV-C is also safe for human beings at certain distances, so a facility doesn’t have to worry about gaining one benefit, while exposing patients and staff to other forms of harm.

Learn More: How UV Light Supports Your Commercial HVAC System’s Infection Prevention Plan

Are There Regulatory or Compliance Standards For Air Filtration?

Certain industries have standards to comply with to prevent infection or ensure process hygiene.

These fast facts illustrate industry-specific national or international standards:

- Healthcare environments rely on ASHRAE (the American Society of Heating, Refrigerating, and Air Conditioning Engineers) Standard 170, concerning healthcare facility ventilation.

- Pharmaceutical manufacturing follows standards 795, 797, and 800 from US Pharmacopoeia (USP).

- Cleanrooms for electronics manufacturing and data centers follow International Standard Organization (ISO) ratings, which range between ISO 1 and ISO 9. The rating is based on what particle sizes are acceptable for that environment.

- Federal Standard 209e regulates cleanrooms in the U.S.

- The Food and Drug Administration (FDA) has also developed standards for handling food and drugs in cleanroom environments.

Don’t See Your Industry? Learn More About How to Adopt Air Filtration Standards

Many industries follow specific guidelines, yet it is important to note that environments without specific regulations can still find resources to help them make the best decisions related to indoor air quality.

For example, in 2023, ASHRAE created Standard 241 to provide guidance for preventing “infectious aerosols” in any indoor environment. This document has been particularly useful for facilities that, prior to the COVID-19 pandemic, had not thought of themselves as needing air distribution systems or products, such as HEPA air filtration.

To determine whether your facility is a critical environment or whether air filtration products could be useful, continue your learning here: Is My Facility a Critical Environment?