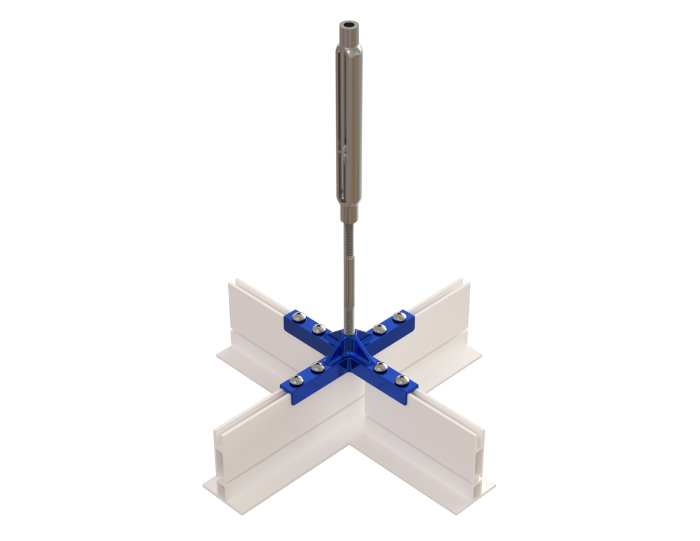

The AJ Manufacturing, Micro-TW grid system is designed for carrying the load of standard filter modules in ISO 4 (Class 10) to ISO 8 (Class 100,000) Cleanroom areas for various industries including but not limited to Aerospace, Biotechnology, Health Care, Microelectronic, Pharmaceutical, Semiconductor, etc. The Micro-TW is a gasket-seal ceiling grid system comprised of 2” (50mm) wide extruded aluminum tee grid members that are bolted together forming a continuous gasketed ledge to receive HEPA or ULPA filters for ultra-clean environments. This ceiling grid system is suspended using ⅜-16 threaded rod with turnbuckles. Each Micro-TW grid member comes factory pre-cut. The Micro-TW main ‘4-way’ connectors are designed for all 4-way intersections. These ‘zinc die-cast’ connectors can be cut to make other grid connectors used at a splice, three-way, inside corners, outside corners, and outside-edge-perimeter connections. The connectors are mounted from the top to the Micro-TW grid, which interconnects to the top threaded boss with ¼-20 hardware. The ‘zinc die-cast’ connector has been specially designed to engage with the top upper area of the main runners and cross-tee sections for accurate grid alignment. All Micro-TW grid intersections are designed for straight cuts to facilitate ease of construction on the job site.

The Micro-TW main runners, cross-tees, and wall-angles are supplied with a powder coat white finish. The sections are shipped in boxes interwoven with paper for protection. The boxes are placed on skids for further protection. Carton sizes are kept to a minimum weight for ease of handling on the job site. For large projects, the grid sections may be “masterpacked” for savings when shipping directly to the job site from our aluminum extruder.

The Micro-TW grid sections are pre-cut for a standard layout of 24 ½” x 48 ½”. This will utilize 46 ½” length cross-tees. The main runners and wall angles are provided in 144” lengths. This layout arrangement will fit most standard filter modules used in the industry. The most commonly used filter module size is 23 ⅝” x 47 ⅝”. Light fixtures are also available that fit this grid layout arrangement. They are designed for the lens to fit the 22 ½” x 46 ½” opening with this grid layout pattern. The Micro-TW grid system can also be used when a 24” x 48” or 48” x 48” layout is required. This will use filter modules that are 23 ⅛” x 47 ⅛” or 47 ⅛” x 47 ⅛”.

The upper part of the Micro-TW main runner, cross-tee, and wall angle is extruded with a ¼-20 threaded boss. This threaded boss is used for attaching the zinc die-casting connectors to the grid extrusion using ¼-20 x ¾ Philips pan head screws. This top thread boss allows for securing a zinc die-cast connector anywhere along the top of the extruded main runners, cross-tees, and wall angles. This top slot can also be used for mounting or clamping down blank panels, filters, and light fixtures with the appropriate tie-down hardware.

Each zinc die-cast connector is tapped for hanging with a ⅜” threaded rod. The recommended hanging center distance is nominally 48” x 48” centers. If the grid system chosen is a 24 ½” x 48 ½” system, the hang centers will be 49” x 48 ½”. It is recommended that an interstitial Strut support system be used in conjunction with the grid system for ease of installation and leveling. The system is provided with ⅜” x 8” threaded rods with both right-hand (RH) and left-hand (LH) threads to be used in conjunction with a 7” body turnbuckle. Enough of these assemblies will be provided for suspension on nominal 4×4 centers. The threaded rod from the turnbuckle up is by others. See drawing layouts for recommendations.

Each project or Micro-TW grid system is shipped with main runners, cross runners, perimeter wall angle, 4-way cross, splice, three ways, perimeter connectors, connecting hardware, RH-LH threaded rods, and turnbuckles. Installation instructions are also provided with each shipment.