Planning for Passing: IEST Leak Testing on ULPA and HEPA Filters

How AJ Manufacturing Helps You Ensure You Meet IEST-RP-CC034 HEPA and ULPA Filter Leak Test Regulations

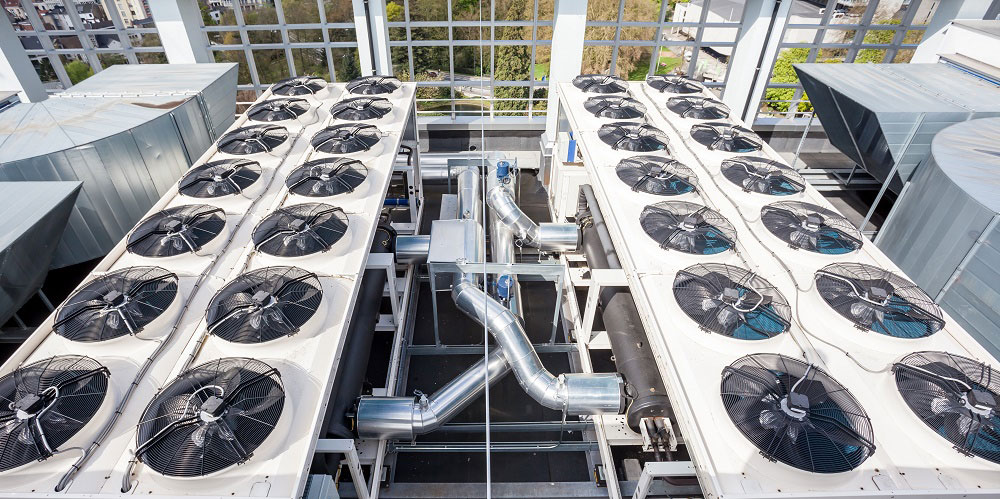

Recent regulations make IEST-RP-CC034 HEPA and ULPA Filter Leak Tests mandatory in many more critical environments and other specialized facilities than ever before.

Building operations managers like you must consider a number of factors to help them ensure their buildings and equipment pass leak tests, both when the commercial HVAC equipment and system are new, and during ongoing check-ups on quality and durability.

This IEST recommended practice (RP) covers definitions, equipment, and procedures for leak-testing HEPA filters and ultralow-penetration (ULPA) air filters in the factory as they are produced, at the job site before installation, and after installation in clean rooms or critical environments and in unidirectional-flow clean-air devices.

The best prevention is quality products with expert installation. Prepare for these tests, first and foremost, by purchasing your commercial HVAC equipment from a reputable fabricator, like AJ Manufacturing, who strives for perfection with every part we make.

Before Commercial HVAC Equipment Testing

Before and after installing your filters and commercial stainless steel HVAC products from AJ Manufacturing on the job site, technicians perform leak testing. Leak testing after installation can be more challenging than the initial testing.

To prepare for the test, you’ll want to know:

- Who is conducting the testing, and what equipment do they use?

- What methods do they use to conduct the leak testing?

- Do they want challenge ports for testing at each air filtration unit? Should they be face mounted or remotely mounted? What fittings are required?

- Are the units ducted, or do they share a plenum?

Gathering information about this during the design phase – long before installation – will prevent costly delays and last-minute modifications when trying to get your new facility online and operating.

During the Integrity Test for Air Filtration

Technicians perform the integrity test on HEPA and ULPA components on supply or exhaust filters using a photometer. The photometer scans the filter’s surface, looking for pinhole leaks that could allow the transmission of contaminants. Lack of integrity would be unacceptable in critical environments.

In fact, you must assume that anything above the ceiling level contains contaminants, and you must prevent it from passing through the filter. That’s why preventing the occurrence of leaks can be difficult.

Preventing Leaks in a Commercial Air Purification System

All air filtration components must be airtight and leak-free in both positive and negative pressure differential conditions, with penetrations kept at a minimum.

You must block every possible leak path with an effective, long-term sealant that withstands building settling, construction vibrations, and everyday use.

Gaskets aren’t good enough in most cases. Instead, consider good, rigid support for hard ceilings that will stay in place under changing pressure conditions, like when someone opens a door. A quality caulk maintains flexibility and seals off potential leaks.

Regular inspections and maintenance, and high quality repair work will also help ensure the clean room continually passes tests year after year.

Our Commitment to Fabricating Quality Commercial HVAC Equipment and Components

As an international fabricator of commercial stainless steel HVAC products, AJ Manufacturing listens to our customers to learn more about the hardships of leak testing so that we can create solutions for them.

As a result, we have:

- Reduced ceiling penetrations by offering integrated lighting with fan filter units.

- Developed challenge manifolds that meet IEST requirements, and have the data to back them up.

- Optimized our knife-edge seals to work under a variety of conditions to minimize leakage opportunities.

Our knowledgeable staff helps you plan your air filtration system, navigate certification, and complete your project correctly the first time.

Work with AJ Manufacturing

Breathe easy knowing that your clean room filtration project is in good hands with AJ Manufacturing, an industry leader in custom and standard stainless steel air distribution products for critical environments.

At AJ Manufacturing, headquartered in Kansas City, Missouri, we engineer each product we fabricate to meet your site’s unique characteristics and challenges, and fabricate them using precision laser cutters, CNC press brakes, and robotic welding arms.

We design every piece made-to-order and thoroughly leak test with our own photometer before we ever package and and ship it to your job site.

To learn more about our products, or to place an order, contact our national sales manager, Amy Van Wagner, at (816) 231-5522 or amyvanwagner@ajmfg.us, or send us a message online.